How to design foundations for onshore wind turbines

Wind turbines convert wind power into clean electricity. To maximize energy output, towers must be tall, sometimes reaching up to 200 meters, to access higher wind speeds. Longer blades increase the sweep area, capturing more wind energy. As a result, there is a trend toward designing larger structures to maximize energy output.

As these structures grow, ensuring their structural safety becomes increasingly important.

The forces acting on the blades and tower are transferred to the ground through the foundation. Given the substantial size of wind turbines, the foundation must provide robust and stable support.

Choosing the right foundation

When it comes to onshore wind turbines, the foundation is an essential element to support these colossal structures. But how do we determine the right foundation type?

The answer lies in the ground beneath. Before we make any decisions, we need to understand the soil properties of the site where the wind turbine will stand. Here are the key considerations:

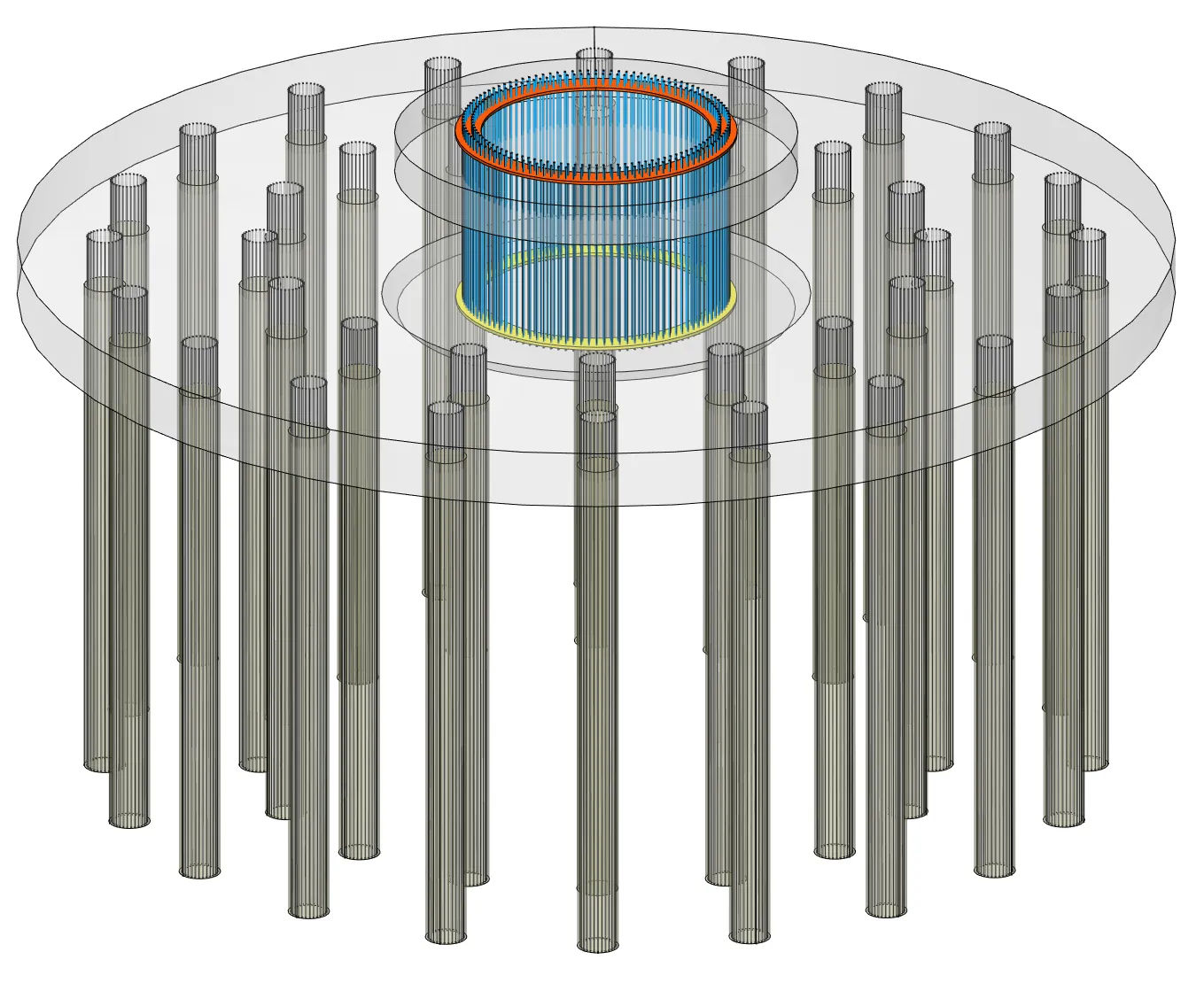

- Weak soil. If the ground's bearing capacity is too low or its low stiffness can lead to large deformations, you'll likely need a piled foundation. These piles reach down to a competent stratum to provide an appropriate support, limiting deformations. However, the piling will significantly increase the construction costs, making it an expensive solution.

- Average soil. In most cases, foundations bearing depth is between 2 and 4 meters below the existing ground surface. Typically, this depth is below the topsoil and weakest superficial strata, so shallow foundations have a stiff and strong enough support.

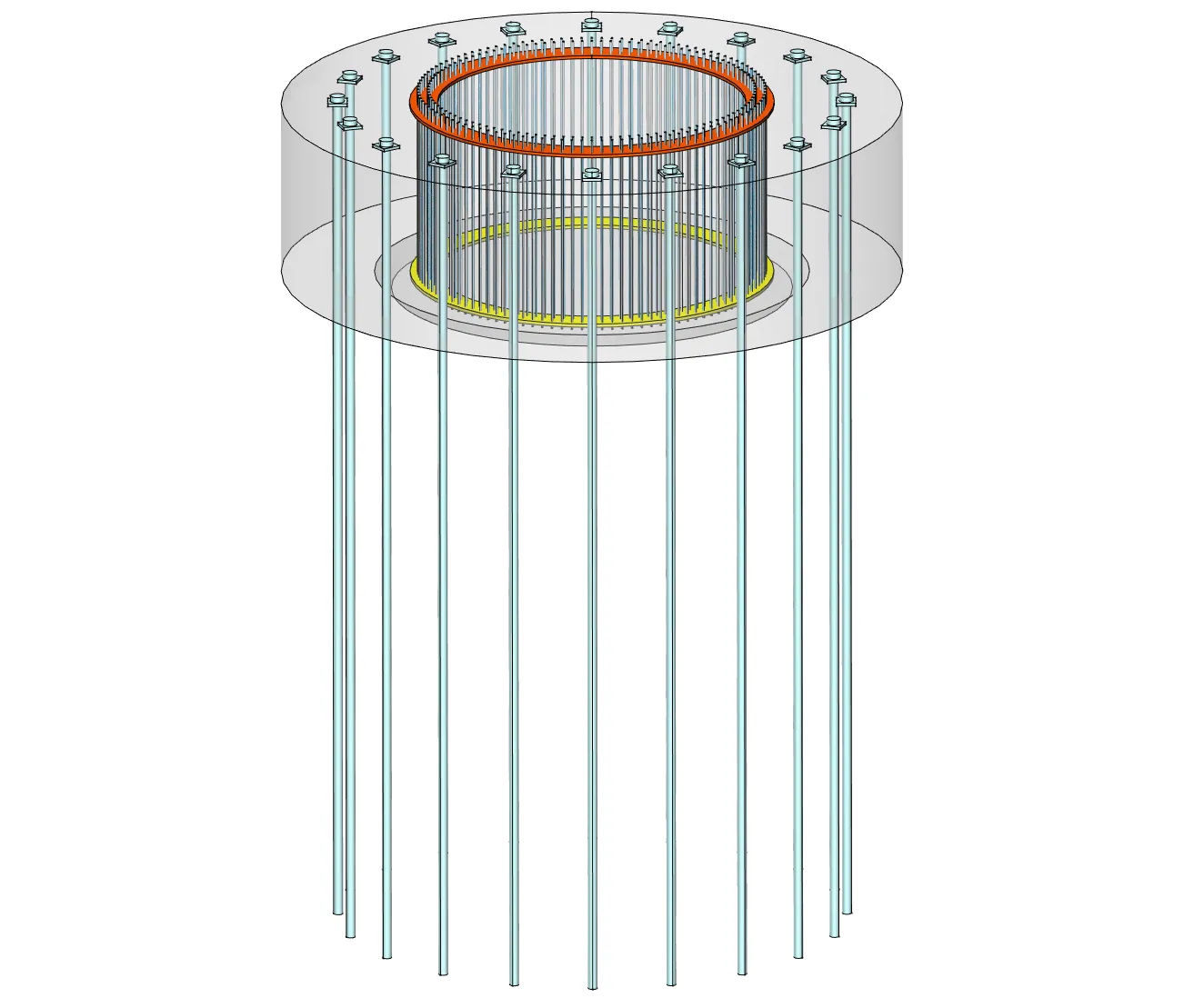

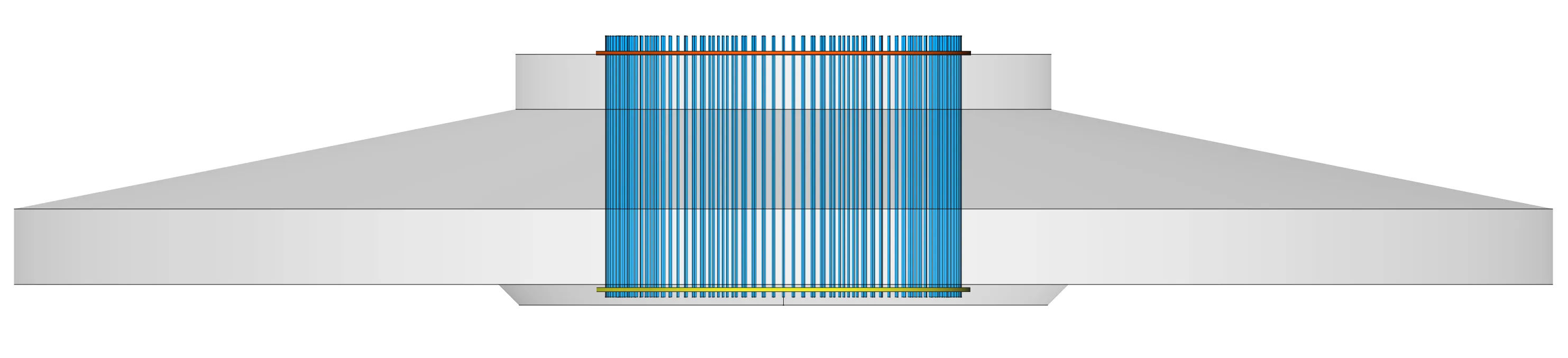

- Competent bedrock. When you're fortunate enough to encounter a relatively shallow and competent bedrock, you might opt to tiedown the slab with rock anchors. This solution allows us to largely reduce the size of the slab, and thus the quantity of both concrete and reinforcing steel. When viable, this solution is the most cost-effective option. For more details, have a look at this shallow vs rock-anchored foundation comparison.

Here's a quick recap:

| Soil properties | Foundation | Cost |

|---|---|---|

| Very deformable or weak | Piled | Expensive |

| Average | Shallow | Moderate |

| Extremely competent | Rock anchored | Cheap |

In most sites, as mentioned earlier, shallow foundations are the go-to choice for supporting onshore wind turbines. However, it's essential to emphasize that the specific soil conditions in your location will determine the ideal foundation type. For example, in the Netherlands, where the soil tends to be muddy and less stable, piled foundations are the standard practice.

As we continue with this post, we'll focus on shallow foundations.

Sizing WTG foundations

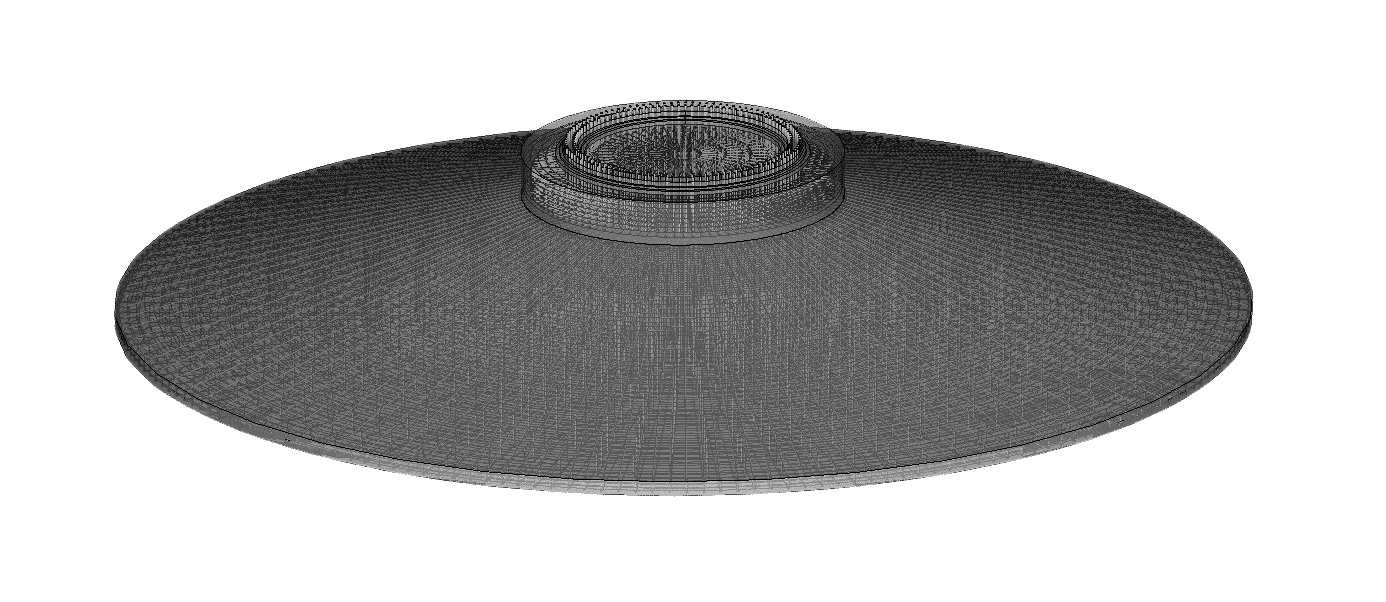

Foundations need to fulfil mainly two functions: they must provide stability to the structure and distribute the forces so the ground can bear the load while limiting deformations. For isolated tower foundations, this translates into the need for enough weight and spread area:

- Ensuring stability by having a foundation with enough weight to counteract destabilizing overturning moments. In practice, WTG foundations can be quite massive, often exceeding 1000 tonnes of reinforced concrete. Additionally, a significant quantity of backfill is placed on top of the slab, which can sum up several hundred tonnes more.

- Preventing overcharging by increasing the foundation base area, keeping the pressure on the ground below its bearing capacity.

However, while stability and bearing capacity are important verifications, they rarely drive the design of onshore wind turbine foundations. An additional and wind turbine specific requirement comes into play: gapping limitation. This requirement is related to cyclic loading, as we'll see later.

Cyclic loading on wind turbine foundations

Up to this point, you might think the foundations of wind turbines are just like those on bridges or buildings—transmitting forces from the structure to the ground. While that's partly true, there's a factor that sets wind turbine structures apart: cyclic loading.

One could argue that bridges experience cyclic loading from vehicles, and that's valid. However, the weight of vehicles is relatively modest compared to the self-weight of the bridge. In the case of wind turbines, the live load is substantial compared to the structure's self-weight, making cyclic loading particularly damaging.

This distinction is the reason behind the numerous standards and guidelines specific to the wind industry put a strong emphasis on fatigue verifications, setting it apart from other civil engineering domains.

Fatigue on wind turbine foundations

The fatigue analysis for wind turbine foundations involves multiple layers of verification.

Ground Bearing Capacity Degradation: When subjected to cyclic loading, the ground may experience a reduction in bearing capacity. Unfortunately, there's no widely established methodology to evaluate this phenomenon. Moreover, conducting laboratory tests to assess this can be both costly and time-consuming. In light of these challenges, specialized standards recommend an alternative approach—ensuring there's no loss of contact between the slab and the soil under operational loads, often referred to as gapping verification. This check often drives the global size of the foundation.

Steel Structural Elements: Fatigue analysis isn't unique to wind turbine foundations; it's relevant in various civil engineering fields. For steel structural elements, standards such as Eurocode 3-9 are entirely dedicated to fatigue assessments. These standards are frequently employed to examine the anchor cage elements, such as plates and bolts.

Reinforced Concrete Elements: Unlike steel, not all standards for reinforced concrete structures specify a comprehensive methodology for fatigue verification. Some might provide only simplified approaches to address this concern. Two of the most commonly referenced texts for reinforced concrete fatigue verification are the FIB Model Code 2010 and DNVGL-ST-C502. These documents use different formulations but both based on damage accumulation.

Takeaways on the design of wind turbine foundations

Designing foundations for wind turbines presents unique challenges compared to other types of structures. These challenges primarily revolve around cyclic loading, which is extremely important in these structures and has a significant impact on the foundation's design.

Understanding the specific requirements is essential for designing foundations that are both safe and cost-effective. If you need support, don't hesitate and get in touch 📧.